Semiconductor Chip Factories Delays A Global Crisis

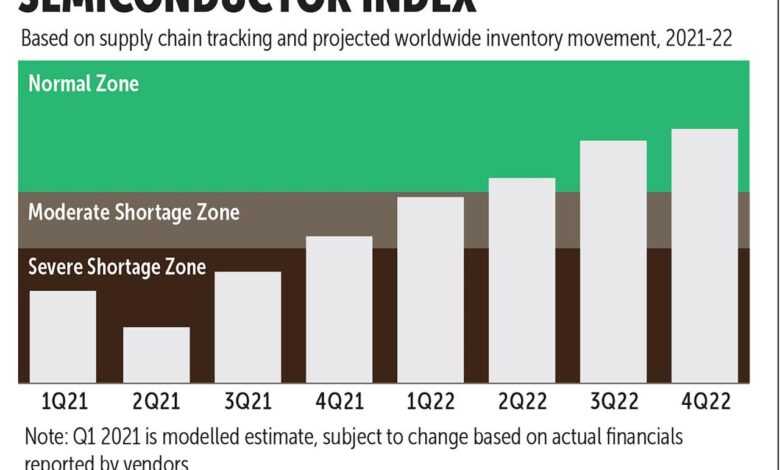

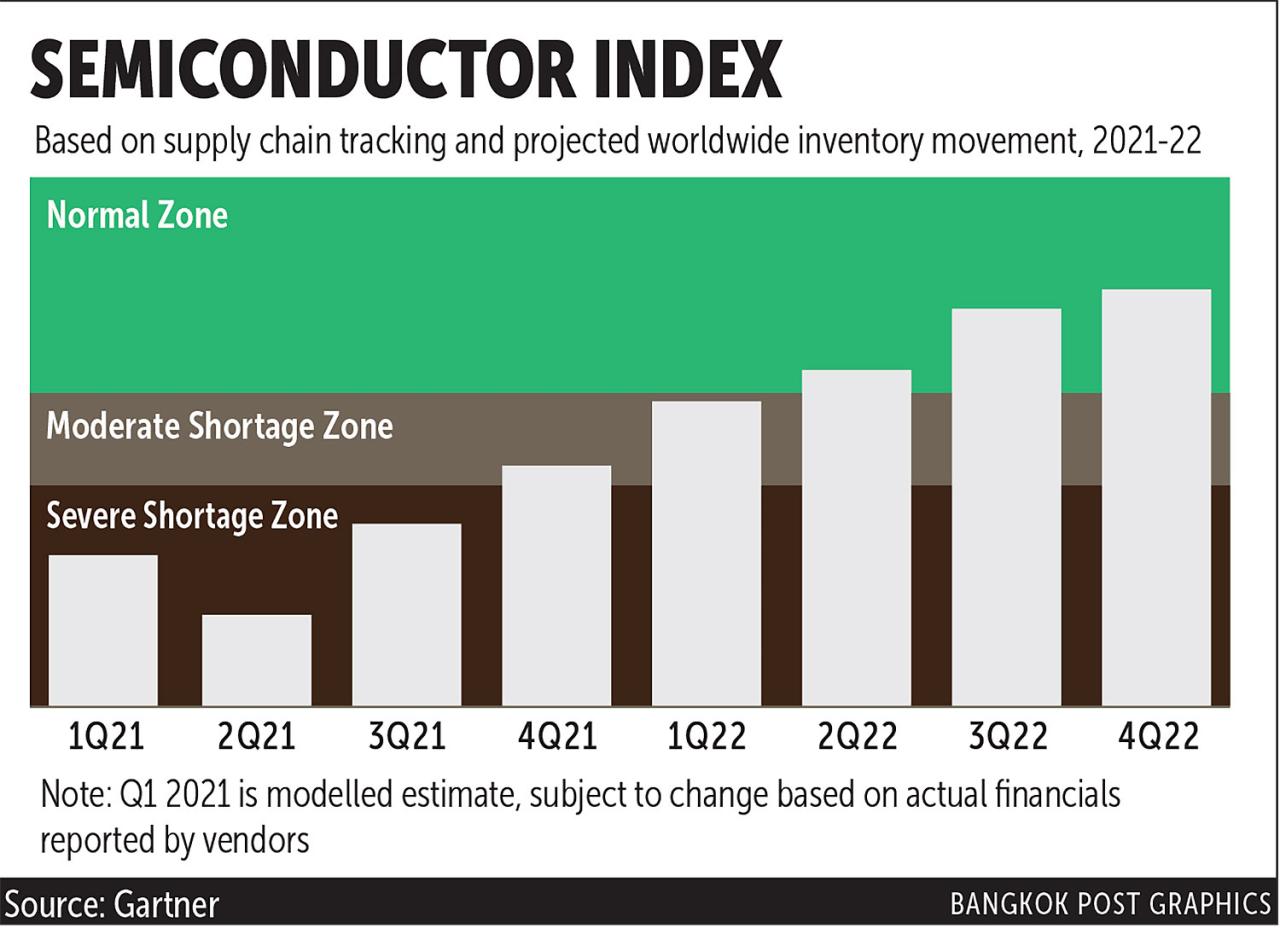

Semiconductor chip factories delays are creating ripples across numerous industries, from automobiles to consumer electronics. The global shortage of these crucial components is impacting production timelines, leading to significant cost increases and potential economic fallout. This complex issue stems from a confluence of factors, including material shortages, supply chain disruptions, and rising demand. Understanding the scope of the problem, the contributing factors, and the potential solutions is crucial to navigating this challenging period.

This in-depth analysis explores the current state of global semiconductor chip manufacturing capacity, examining the leading players, their production levels, and the manufacturing technologies employed. We’ll delve into the factors driving these delays, such as material shortages, supply chain disruptions, and geopolitical instability. The impact on various industries, including automobiles, consumer electronics, and renewable energy, will also be examined, along with potential solutions and a look into the future outlook.

Global Semiconductor Chip Manufacturing Capacity

The global semiconductor industry is a complex web of intricate manufacturing processes, constantly evolving to meet the demands of a technologically advanced world. Understanding the current capacity, geographical distribution, and key players is crucial to grasping the intricate dynamics of this essential sector. This exploration delves into the current state of global semiconductor chip manufacturing, providing insights into production levels, manufacturing processes, and technological advancements.The semiconductor industry is not static; it’s a dynamic landscape shaped by technological breakthroughs, market fluctuations, and geopolitical factors.

Capacity expansions and process improvements are frequently occurring, reflecting the industry’s continuous drive for efficiency and innovation.

Current Global Manufacturing Capacity

The global semiconductor chip manufacturing capacity is substantial, yet highly concentrated geographically. The production of these crucial components is not evenly distributed, but instead concentrated in specific regions. This concentration influences pricing, supply chains, and geopolitical stability.

Geographical Distribution of Fabrication Facilities

The major chip fabrication facilities, or fabs, are concentrated in a few key regions. East Asia, particularly Taiwan and South Korea, dominates this sector, hosting many leading semiconductor manufacturers. The United States and Europe also possess significant fabrication capabilities, although to a lesser extent. This geographical concentration reflects historical investment and technological advancements.

Key Players and Production Levels

Several major players dominate the semiconductor manufacturing landscape. Companies like TSMC (Taiwan Semiconductor Manufacturing Company), Samsung Electronics, and Intel are leading the charge, contributing substantially to global production. Their production levels are influenced by factors like market demand, investment in new facilities, and technological advancements in chip design and fabrication.

Manufacturing Processes and Technologies

The manufacturing processes for semiconductor chips are highly sophisticated and complex. Companies employ various technologies, including photolithography, etching, and deposition, to create intricate patterns on silicon wafers. The degree of automation, the precision of equipment, and the sophistication of the design rules all contribute to the complexity of the production process. Different companies may use slightly different approaches or variations in these processes, and the technological advancements in these areas are continuous.

Intel’s emphasis on developing its own chip design and manufacturing capabilities, for instance, contrasts with TSMC’s focus on providing foundry services. This strategic difference significantly impacts their production levels and overall market position.

Top 5 Countries with Highest Semiconductor Chip Production Capacity (2023 Estimate)

| Country | Production Capacity (in millions of chips per year) | Leading Companies | Manufacturing Technology |

|---|---|---|---|

| Taiwan | ~400 | TSMC, UMC | 7nm, 5nm, and beyond |

| South Korea | ~250 | Samsung Electronics | 5nm, 3nm, and beyond |

| United States | ~100 | Intel, GlobalFoundries | 14nm, 10nm, and beyond |

| Japan | ~50 | Sony, Renesas | 10nm, 7nm, and beyond |

| Netherlands | ~30 | ASML, TSMC (some facilities) | EUV lithography, advanced nodes |

Note: Production figures are estimates and can vary depending on the source and specific criteria used for calculation. Leading companies often have production facilities in multiple countries, contributing to the complexity of these estimations.

Ever wondered how delays at semiconductor chip factories are impacting everything, even the high-fashion world? The production bottlenecks are causing ripples across industries, and even the glamorous Saint Laurent Dior Paris Fashion Week saint laurent dior paris fashion week might feel the effects, with potentially delayed deliveries of high-end tech accessories. Ultimately, these factory delays will continue to have far-reaching consequences across various sectors.

Factors Contributing to Delays

The semiconductor industry, a cornerstone of modern technology, is facing significant challenges in keeping up with the relentless demand. Construction delays at chip factories are not isolated incidents but a complex web of interwoven factors, primarily driven by the confluence of global supply chain issues, escalating material costs, and geopolitical uncertainties. These hurdles are impacting production timelines, pushing back the availability of crucial components for countless products, from smartphones to automobiles.

Material Shortages and Supply Chain Disruptions

Global supply chains have been severely tested in recent years, and the semiconductor industry is no exception. Material shortages, particularly of essential components like rare earth minerals, silicon wafers, and specialized chemicals, have significantly hampered production. This is further exacerbated by logistical bottlenecks, port congestion, and labor shortages within the supply chain itself. The domino effect of these issues has made it increasingly difficult and expensive to procure the necessary materials for chip fabrication.

Geopolitical Instability and Trade Tensions

Geopolitical instability and trade tensions further complicate the already strained landscape. Trade wars, sanctions, and other international conflicts can disrupt the flow of materials and components, impacting the availability of essential resources for chip manufacturing. These disruptions often lead to increased costs and delays in the construction and operation of new factories. Examples include the ongoing trade disputes and sanctions affecting certain regions, which have limited access to specific materials and technologies crucial for semiconductor production.

Rising Demand and Production Timelines, Semiconductor chip factories delays

The unrelenting demand for semiconductors across various sectors, from consumer electronics to automotive, has put immense pressure on production timelines. The exponential growth in the use of semiconductors in various products has outpaced the capacity of existing factories. This surge in demand has driven up the cost of raw materials and the need for more sophisticated and advanced manufacturing facilities, inevitably leading to longer construction times for new factories.

The insatiable appetite for computing power and connectivity across the board has created an unanticipated and significant hurdle in the semiconductor industry’s ability to keep pace.

Specific Events and Crises Impacting the Industry

Several events have highlighted the fragility of the global semiconductor supply chain. The COVID-19 pandemic, with its associated lockdowns and disruptions to global logistics, caused significant bottlenecks in the supply of materials and components. The war in Ukraine further exacerbated these issues, impacting the availability of specific materials and disrupting global trade routes. The impact of these crises is readily visible in the delayed completion of new chip fabrication plants.

Cost Comparison Across Regions

| Region | Raw Material Cost | Labor Cost | Energy Cost |

|---|---|---|---|

| North America | High | High | Moderate |

| Southeast Asia | Moderate | Low | Moderate |

| Europe | High | High | Moderate |

| China | Moderate | Low | Low |

Note: Costs are relative and can fluctuate based on specific material types, labor skills, and energy prices. The table provides a general overview and does not represent an exhaustive comparison.

Impact on Industries and Consumers

The global semiconductor chip shortage has reverberated through various industries, causing significant disruptions and impacting consumer products and pricing. This bottleneck, stemming from a complex interplay of factors, has far-reaching consequences, extending beyond the immediate production of chips. The delays have not only hampered the output of crucial goods but have also led to a cascade of issues for consumers, from increased prices to product shortages.

Ripple Effects on Downstream Industries

The semiconductor chip shortage has created a ripple effect across multiple industries, impacting their production and supply chains. Automotive manufacturing has been severely affected, with production lines grinding to a halt as automakers struggle to obtain the necessary components. Consumer electronics companies have also experienced significant setbacks, impacting the availability and production of smartphones, laptops, and other devices.

Even the renewable energy sector, reliant on semiconductor chips for inverters and other crucial components, has faced challenges in scaling production.

Those semiconductor chip factory delays are really throwing a wrench in the works, aren’t they? It’s impacting everything from the latest gadgets to, surprisingly, the housing market near NYC. Housing market near NYC is experiencing some interesting ripple effects, with prices adjusting in response to the overall economic climate. Ultimately, these chip factory delays are a reminder of how interconnected our modern economy really is.

Impact on Consumer Products and Pricing

The shortage has translated directly into higher prices for consumer products. Manufacturers are forced to increase costs to compensate for the higher prices of chips, ultimately passing those costs onto consumers. This has resulted in increased prices for a wide range of products, including smartphones, laptops, and even appliances. The availability of some products has also been severely curtailed, leading to longer wait times and limited choices for consumers.

Semiconductor chip factory delays are a real headache, impacting everything from your phone to your car. It’s a complex issue, but one contributing factor could be the recent news surrounding Felicia Snoop Pearson and Ed Burns’s wire work, as detailed in this fascinating article felicia snoop pearson ed burns wire. Ultimately, these delays are causing ripple effects throughout the supply chain, impacting consumers and businesses alike.

Examples of Impacts on Consumer Electronics

The impact on consumer electronics is particularly evident. Smartphone production has been significantly affected, resulting in delays and limited availability of new models. Laptop manufacturers have struggled to meet demand, causing shortages and price increases. Even smaller consumer electronics, like gaming consoles and smart home devices, have been affected, with reduced production and altered release schedules.

Global semiconductor chip factory delays are causing ripples across numerous industries. The ongoing geopolitical tensions, particularly the recent developments surrounding the Biden-Israel-Hamas cease fire biden israel hamas cease fire , are adding further complexity to the already strained supply chain. These delays are impacting everything from consumer electronics to automotive production, highlighting the interconnectedness of global economies.

Long-Term Implications for the Global Economy

The long-term implications of the semiconductor chip shortage extend beyond immediate price increases and product shortages. The disruptions in supply chains and manufacturing processes could lead to decreased productivity and innovation across multiple sectors. This could result in slower economic growth and potentially higher inflation in the long run. Moreover, the reliance on a global supply chain for semiconductors highlights the vulnerabilities of interconnected economies.

Projected Impact on Industries’ Production Output

The following table illustrates the projected impact on different industries’ production output and pricing due to the semiconductor chip shortage. It’s crucial to understand that these projections are estimations, and the actual impact could vary based on the duration and severity of the shortage.

| Industry | Projected Output Reduction (%) | Impact on Prices (%) |

|---|---|---|

| Automotive | 15-20 | 5-10 |

| Consumer Electronics | 10-15 | 3-7 |

| Renewable Energy | 5-10 | 2-5 |

| Industrial Machinery | 8-12 | 4-8 |

Solutions and Mitigation Strategies

The escalating demand for semiconductors, coupled with protracted delays in factory construction, necessitates proactive solutions and resilient strategies. Addressing these challenges requires a multifaceted approach involving government incentives, technological innovation, and supply chain optimization. This section explores potential solutions and mitigation strategies to navigate the current landscape and prepare for future demands.Addressing the bottlenecks in semiconductor manufacturing requires a coordinated effort.

Semiconductor chip factory delays are a real headache for global tech companies. These delays are impacting everything from car production to the latest gadgets. The ripple effect is widespread, and it’s not just about the cost of components. Geopolitical factors like tensions in the region surrounding us russia nuclear space pakistan asia are also playing a part, further complicating the already challenging supply chain.

This, in turn, is creating uncertainty and pushing back the timelines for the release of new products, ultimately affecting consumers.

Improved forecasting, strategic investments in infrastructure, and adaptable supply chains are crucial for mitigating future delays and ensuring consistent product availability.

Potential Solutions to Address Construction Delays

The protracted timelines for semiconductor fabrication plant construction highlight the need for streamlined permitting processes and expedited infrastructure development. Collaboration between government agencies, developers, and industry stakeholders is essential. Incentivizing faster permitting approvals and providing targeted funding for critical infrastructure components, such as water and power grids, can significantly reduce construction durations.

Strategies to Improve Supply Chain Resilience and Efficiency

Diversifying supply chains and fostering closer collaborations between semiconductor manufacturers and component suppliers are crucial for enhancing resilience. Developing robust, redundant supply routes can mitigate disruptions caused by geopolitical events or natural disasters. Implementing advanced logistics and inventory management systems can improve efficiency, reduce lead times, and enhance responsiveness to changing demand.

Innovative Solutions to Reduce Manufacturing Lead Times

Advanced automation, precision manufacturing techniques, and process optimization can significantly reduce manufacturing lead times. Implementing advanced robotics, AI-driven quality control, and optimized production flows can enhance throughput and reduce defects. The adoption of 3D chip stacking and advanced packaging technologies can further shrink device sizes and decrease manufacturing time.

Framework for Forecasting and Managing Future Demand Fluctuations

Accurate forecasting of future demand is essential for optimizing production capacity and mitigating potential shortages. Implementing advanced analytics, machine learning algorithms, and real-time market intelligence can improve forecasting accuracy. Utilizing historical sales data, market trends, and technological advancements can enable more precise predictions. Developing contingency plans for unexpected surges or declines in demand is crucial for maintaining production stability.

For instance, flexible production lines that can quickly adapt to shifts in product demand, as seen in the automotive industry’s response to electric vehicle adoption, can ensure responsiveness.

Government Incentives and Policies

Government incentives and policies play a vital role in stimulating semiconductor chip production. A well-structured framework can attract investment, promote innovation, and foster a robust domestic industry.

| Country | Incentive Type | Target Industries | Details |

|---|---|---|---|

| United States | Tax Credits | Semiconductor Fabrication | Targeted tax credits for companies investing in new facilities and equipment. |

| South Korea | Government Funding | Advanced Packaging | Government-backed loans and grants for research and development in advanced packaging technologies. |

| Taiwan | Land Use Policies | Chip Design and Manufacturing | Streamlined land acquisition processes for semiconductor manufacturing facilities. |

| Netherlands | Investment Incentives | Chip Design and Manufacturing | Attractive tax breaks and subsidies for companies establishing cutting-edge research and development facilities. |

| Singapore | Research Grants | Semiconductor Manufacturing | Funding for research and development in advanced materials and processes for semiconductor production. |

Future Outlook and Predictions

The semiconductor chip industry, a cornerstone of modern technology, faces an uncertain future due to persistent manufacturing delays. Predicting the exact trajectory is complex, as numerous interconnected factors influence the market. However, analyzing expert opinions, potential technological advancements, and emerging market trends allows for a reasoned assessment of the industry’s likely path.The long-term impacts of these delays extend beyond immediate production bottlenecks.

The ripple effect through global supply chains, impacting everything from consumer electronics to automotive manufacturing, will continue to be a significant concern. This necessitates a proactive approach to mitigating the consequences and fostering resilience in the face of future disruptions.

Expert Opinions on Future Trajectory

Industry experts generally agree that the semiconductor chip industry will continue its growth trajectory, albeit with potential fluctuations. The increasing demand for chips across diverse sectors, including artificial intelligence, renewable energy, and the Internet of Things, is expected to drive continued innovation and investment. However, the recent delays highlight the vulnerability of the global supply chain and the importance of diversifying manufacturing capabilities.

For example, the ongoing conflict in certain regions has demonstrated how geopolitical instability can significantly disrupt production timelines and availability.

Potential Long-Term Impacts on Global Markets

The prolonged delays in semiconductor chip production have already caused substantial disruptions to global markets. These disruptions are anticipated to persist, potentially impacting consumer spending and economic growth. For instance, the automotive industry has faced significant production cuts due to chip shortages, leading to delays in vehicle deliveries and affecting sales figures. Similar impacts are expected in other sectors, including consumer electronics and industrial machinery.

Potential Technological Advancements

Several technological advancements could potentially accelerate chip manufacturing. These include improvements in chip design and lithography, which may enable smaller and more efficient chips. The development of new materials and manufacturing processes, such as extreme ultraviolet (EUV) lithography, is crucial in achieving faster and more efficient production. Moreover, the increasing adoption of automation and AI in manufacturing processes will likely contribute to faster and more cost-effective production.

The use of advanced materials and processes is also critical to increase the performance and functionality of chips.

Potential New Market Entrants and their Impact

The current challenges in the semiconductor industry may provide opportunities for new market entrants. These new players could offer innovative solutions and alternative manufacturing methods, potentially challenging the established market leaders. For example, the rise of companies focused on specific niche markets or specialized chip types could reshape the landscape of the industry. However, substantial capital investment and expertise in chip design and manufacturing are necessary to successfully enter this highly competitive market.

Projected Growth of the Semiconductor Industry (2024-2029)

| Year | Estimated Growth Rate (%) | Estimated Market Size (USD Billion) |

|---|---|---|

| 2024 | 5.2 | 520 |

| 2025 | 5.8 | 550 |

| 2026 | 6.1 | 585 |

| 2027 | 6.5 | 625 |

| 2028 | 6.8 | 670 |

| 2029 | 7.2 | 715 |

The table above illustrates a projected growth in the semiconductor industry from 2024 to 2029. The projections are based on various market research data and assume a sustained demand for semiconductors across various sectors. These figures are estimates and may vary depending on unforeseen events and market fluctuations.

Final Thoughts

The semiconductor chip factory delays are a multifaceted crisis with far-reaching consequences. From production bottlenecks to rising costs and consumer product shortages, the impact is undeniable. While the challenges are substantial, potential solutions and mitigation strategies exist. Understanding the factors behind the delays, the ripple effects across industries, and the potential solutions is crucial for navigating this period and ensuring a more resilient and efficient future for the semiconductor industry.

FAQs: Semiconductor Chip Factories Delays

What are the primary reasons for the increase in semiconductor chip factory delays?

Several factors contribute to the delays, including material shortages, supply chain disruptions, increased demand, and geopolitical instability. The intricate nature of the global supply chain makes it vulnerable to unforeseen events that can disrupt production.

How will these delays impact consumer electronics products?

Delays in semiconductor chip production will lead to shortages and price increases for consumer electronics products. This could result in longer wait times for new devices or a reduction in features to reduce costs.

What government incentives are being implemented to address the delays?

Many governments are implementing incentives to encourage investment in semiconductor chip production. These incentives vary from tax breaks to funding research and development to attract companies to establish or expand facilities in their countries.

What is the projected impact on different industries’ production output?

The projected impact on production output varies significantly depending on the industry. Industries heavily reliant on semiconductors, like automobiles and consumer electronics, will experience more substantial reductions compared to industries with less dependence.