California State Faculty Contract A Deep Dive

California State faculty contract details the terms and conditions governing employment for academics at California State Universities. This in-depth look explores everything from the historical evolution of these contracts to the current legal frameworks, compensation structures, and potential future changes. Understanding these contracts is crucial for both faculty and university administrations.

The document delves into the key provisions, including employment terms, compensation packages, benefits, and performance expectations. It also analyzes the negotiation process, highlighting the roles of various stakeholders and providing a step-by-step guide. The intricacies of academic freedom and responsibilities are also thoroughly examined, offering valuable insights into the unique aspects of faculty work.

Overview of California State Faculty Contracts

California State University faculty contracts are legally binding agreements outlining the terms and conditions of employment. These documents meticulously detail the responsibilities, compensation, and benefits associated with each position, ensuring a clear understanding between the institution and the faculty member. Understanding these contracts is crucial for both maintaining a productive work environment and protecting the rights of all involved parties.California State faculty contracts are comprehensive documents that address a multitude of issues, including employment terms, compensation, benefits, and performance expectations.

These contracts are carefully crafted to navigate the complex legal landscape of higher education employment in California.

Key Elements of California State Faculty Contracts

California State faculty contracts are designed to establish a clear understanding of the rights and responsibilities of both the institution and the faculty member. This includes outlining specific obligations, responsibilities, and the scope of employment. These contracts are legally binding and serve as a crucial reference point for both parties involved.

Employment Terms

Employment contracts typically define the start and end dates of employment, the position title, and the specific duties associated with the role. They often include provisions for leaves of absence, such as for parental leave or medical leave. These provisions are designed to protect the faculty member’s rights while ensuring the institution’s operational needs are met.

Compensation

Compensation details are fundamental to any employment contract. These details encompass salary, benefits, and any additional forms of compensation, like stipends or research grants. Compensation structures vary based on the specific position and the faculty member’s experience and qualifications. Compensation also often includes details about salary increases, merit-based pay adjustments, and any potential bonuses.

Benefits

California State faculty contracts typically Artikel the benefits package available to employees, including health insurance, retirement plans, and paid time off. These benefits are designed to attract and retain qualified faculty members. The specific benefits provided vary based on the contract type, the institution, and the faculty member’s position.

Performance Expectations

Performance expectations are crucial for ensuring the faculty member meets the institution’s academic standards. Contracts specify the criteria for evaluating performance, including teaching evaluations, research output, and service contributions. This clarity is critical to maintaining academic standards and promoting a positive learning environment.

California State faculty contract negotiations are proving tricky, with significant disagreements on key points. However, recent headlines about the return of Romeo Gigli to Marrakech ( return of romeo gigli marrakesh ) seem to highlight a different kind of drama, one hopefully less contentious than the faculty contract negotiations. Ultimately, both situations highlight the complex dynamics of public and private interests at play.

Types of California State Faculty Contracts

This table Artikels the common types of faculty contracts found at California State Universities. Each type has unique characteristics regarding tenure, responsibilities, and compensation.

| Contract Type | Tenure Status | Typical Duties | Compensation |

|---|---|---|---|

| Tenure-Track | Aspiring for tenure | Teaching, research, and service | Competitive salary, comprehensive benefits |

| Non-Tenure-Track | No tenure | Teaching, research, or service | Salary commensurate with experience and position |

| Lecturer | No tenure | Teaching primarily | Generally lower salary than tenure-track, variable benefits |

Historical Context of Contracts

The evolution of faculty contracts at California State Universities reflects a complex interplay of legal precedents, legislative actions, and the changing academic landscape. Understanding this history provides crucial context for comprehending the current framework and potential future directions. The development of these contracts isn’t a linear progression, but rather a series of adjustments and adaptations to meet evolving needs and societal expectations.From early models emphasizing institutional control to more recent emphasis on faculty rights and responsibilities, the journey reveals a dynamic relationship between the university and its teaching staff.

This historical perspective illuminates the rationale behind the current provisions and allows for a deeper understanding of the potential challenges and opportunities ahead.

Legislative and Judicial Influences

Significant legislative changes and court decisions have profoundly shaped the nature of faculty employment in California State Universities. These events, often driven by broader societal trends and legal interpretations, have led to evolving rights and responsibilities for both faculty and institutions.

Timeline of Key Events

The development of faculty contracts wasn’t a singular event but a series of actions and responses over time. The following timeline highlights crucial moments that impacted the trajectory of faculty employment at California State Universities:

- 1960s-1970s: The rise of the academic labor movement saw increased unionization and collective bargaining efforts. These efforts, fueled by broader social and political changes, led to the recognition of faculty as a distinct group with specific employment needs. The emergence of teacher’s unions influenced the development of contractual agreements.

- 1980s: Legislation addressing tenure and promotion processes, and the definition of academic freedom within the university setting, was passed. This era witnessed an increased emphasis on formalizing the conditions of employment. The legal interpretations of academic freedom influenced the development of contractual language.

- 1990s-2000s: The increasing pressure on higher education institutions to control costs led to discussions around compensation models and the impact of state funding on faculty employment. The economic climate profoundly affected faculty compensation and benefits. Discussions around workload and compensation structures became more prevalent.

- 2010s-Present: Contemporary issues, such as evolving teaching methodologies, online education, and diversity and inclusion initiatives, have influenced discussions around the role of faculty and the types of support they require. New challenges, including the impact of technology and evolving pedagogical approaches, were addressed.

Impact of Specific Legislation

Several key legislative acts have directly influenced faculty contract provisions. These acts often reflect broader societal changes and evolving understandings of the role of higher education in society. The following table details some crucial pieces of legislation and their impact:

| Legislation | Impact on Faculty Contracts |

|---|---|

| California Education Code | This code provides a framework for the structure of California State University systems, including the conditions of employment for faculty. It dictates crucial aspects of faculty responsibilities, compensation, and rights. |

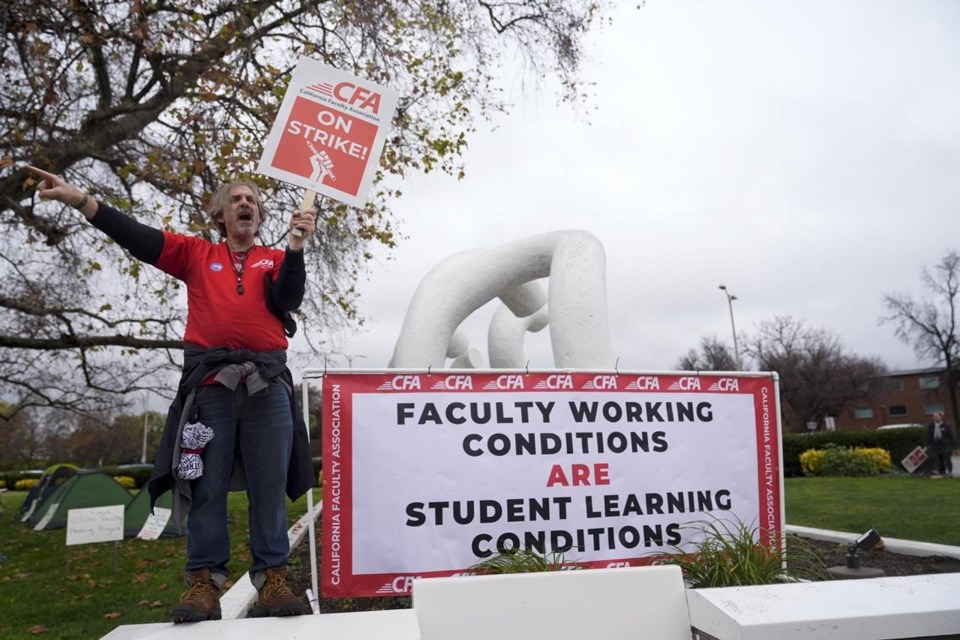

| Collective Bargaining Laws | These laws mandate the process of collective bargaining between faculty unions and university administrations, leading to the inclusion of specific provisions addressing salaries, workloads, and grievance procedures in faculty contracts. The existence of collective bargaining rights influenced the establishment of formal procedures and rights for faculty. |

| State Funding Models | Variations in state funding have influenced the ability of universities to offer competitive salaries and benefits to faculty, impacting the structure of faculty contracts and influencing compensation levels. State budget limitations influenced the negotiation of faculty compensation and benefits. |

Contract Negotiation Processes

Negotiating a California State faculty contract is a complex process, involving a delicate balance between the needs of the faculty member and the university’s administrative priorities. Understanding the intricacies of this process is crucial for both parties to ensure a fair and mutually beneficial agreement. This process often involves several key players and a structured approach, designed to achieve a satisfactory outcome for all parties.The negotiation process isn’t a one-size-fits-all scenario.

It’s influenced by numerous factors, including the specific college or university, the department’s needs, and the individual faculty member’s expertise and experience. However, certain general principles and steps typically guide the process, ensuring a productive exchange of ideas and concerns.

Typical Negotiation Stages

The negotiation of a California State faculty contract generally follows a predictable sequence of events. This involves multiple rounds of communication, proposals, and counter-proposals, ultimately culminating in a signed agreement. A clear understanding of these stages is vital for both parties.

Roles of Stakeholders

Several stakeholders play vital roles in the negotiation process. Understanding their individual responsibilities and perspectives is key to navigating the complexities of the process.

- Faculty Member: The faculty member is the central figure in the negotiation, responsible for articulating their professional needs, expectations, and concerns regarding the terms of employment. They need to research similar contracts to understand industry standards and have a clear understanding of their role and responsibilities within the university.

- Department Chair/Head: The department chair acts as a liaison between the faculty member and the university administration. They represent the department’s interests and contribute to the discussion of the faculty member’s role within the department’s overall goals and objectives.

- University Administration: University administrators, such as the dean or provost, represent the institution’s overall interests, including budget constraints, departmental priorities, and adherence to institutional policies. Their role is to ensure the contract aligns with the university’s strategic goals.

- Union Representatives (if applicable): In cases where faculty members are represented by a union, union representatives play a crucial role in advocating for the collective interests of the faculty members and ensuring that the contract reflects fair and equitable terms.

Step-by-Step Guide to Negotiation

A structured approach can significantly improve the efficiency and effectiveness of the negotiation process. This systematic process can facilitate productive communication and facilitate reaching a mutual agreement.

- Initial Contact and Information Gathering: The faculty member and the department chair should initiate contact to discuss initial expectations and gather essential information, such as salary ranges, benefits packages, and typical contract terms for similar roles. This proactive step ensures a shared understanding of the negotiation’s starting point.

- Proposal and Counter-Proposals: The faculty member presents their proposed contract terms, including salary expectations, benefits, and research support. The university administration responds with counter-proposals, considering the faculty member’s qualifications and the university’s budget constraints. This iterative process allows for adjustments and compromises.

- Negotiation Sessions: Regular meetings between the faculty member, department chair, and university representatives are essential for discussing and resolving discrepancies. This dialogue is crucial for reaching a mutually agreeable contract.

- Documentation and Review: All agreed-upon terms should be meticulously documented in writing. Both parties should thoroughly review the finalized contract to ensure that it accurately reflects the agreed-upon terms and conditions.

- Contract Signing and Implementation: Once both parties are satisfied with the final agreement, the contract is formally signed. The contract’s provisions are implemented according to the agreed-upon timeline.

Legal and Regulatory Frameworks

California State faculty contracts are intricately woven into a complex tapestry of state laws, university policies, and legal precedents. Understanding these frameworks is crucial for both faculty and administrators to ensure fair and equitable treatment, while upholding the integrity of the educational mission. These legal underpinnings provide the foundation for the negotiation and enforcement of faculty contracts, impacting everything from compensation to academic freedom.Navigating the intricacies of these frameworks can be challenging.

California’s diverse legal landscape, coupled with the evolving nature of higher education, necessitates a deep understanding of the relevant statutes, regulations, and case law to ensure contracts are compliant and effectively protect the rights and responsibilities of all parties involved. This section will delve into the key legal and regulatory components shaping California State faculty contracts.

State Laws Governing Faculty Contracts

California’s labor laws, notably the Education Code and the California Labor Code, provide a crucial framework for faculty contracts. These codes Artikel provisions related to employment conditions, wages, and working hours, directly influencing the terms of faculty agreements. For example, the Education Code often specifies minimum qualifications and salary ranges for certain academic positions, creating a baseline for contract negotiations.

University Policies and Procedures

Each university within the California State University system has its own set of policies and procedures that complement state laws. These policies typically detail internal processes for contract development, review, and dispute resolution. These procedures are vital in ensuring consistent application of legal principles across the system. For instance, specific policies might address academic freedom, tenure processes, or grievance procedures, all of which are reflected in faculty contracts.

Legal Precedents Impacting Faculty Contracts

Court decisions and administrative rulings establish precedents that influence the interpretation and application of legal principles in faculty contracts. Cases involving academic freedom, tenure, and contract violations set significant legal precedents. For example, a court ruling regarding the limits of academic freedom in a particular context can directly impact the terms of future contracts, affecting the specific language used to define this right within the agreement.

The California State faculty contract negotiations are proving tricky, with both sides entrenched in their positions. Meanwhile, the tragic events surrounding the armorer Alec Baldwin’s involvement in the “Rust” shooting, as detailed in armorer Alec Baldwin rust shooting , highlight the complex safety considerations in various industries, including the potential for similar issues within the education sector. Ultimately, these external events bring a new layer of pressure to the faculty contract talks in California.

Such rulings often serve as a benchmark for future negotiations and disputes, ensuring consistency in the application of legal principles.

Role of the Collective Bargaining Agreement

In some instances, collective bargaining agreements between the university and faculty unions can significantly shape faculty contracts. These agreements frequently address issues like compensation, benefits, and working conditions. The provisions within a collective bargaining agreement supersede or complement the general provisions in state laws and university policies, creating a specific framework tailored to the interests of both parties.

Understanding the scope and influence of these agreements is critical for comprehensive analysis of the legal landscape surrounding faculty contracts.

Compensation and Benefits Analysis

California State University faculty compensation and benefits are complex, varying significantly across departments, ranks, and institutions. Understanding these nuances is crucial for prospective faculty members seeking to assess their future financial well-being. This section delves into the detailed structures, highlighting the factors influencing these differences.Faculty compensation is not a static entity but rather a dynamic system responding to economic conditions, institutional priorities, and collective bargaining agreements.

This dynamic nature ensures that compensation structures are not fixed but can be adjusted in response to changing circumstances.

Compensation Structures for Various Faculty Positions

Faculty compensation packages are typically structured around a base salary, which varies greatly based on the faculty member’s rank (instructor, assistant professor, associate professor, full professor), years of experience, and the specific requirements of the position. Additionally, many positions have supplemental components, such as research grants, teaching stipends, or fees associated with external activities. Furthermore, some institutions may offer incentives based on specific research areas or areas of expertise.

- Instructor: Entry-level positions often feature lower base salaries compared to higher ranks. The compensation package may include a combination of base salary, teaching loads, and potential opportunities for research or grant funding.

- Assistant Professor: These positions generally involve a higher base salary than instructors and may include additional benefits like professional development funds or reduced teaching loads to allow time for research.

- Associate Professor: Associate professors are typically compensated at a higher level than assistant professors, reflecting increased experience and responsibilities. This often includes more substantial research funding and teaching opportunities.

- Full Professor: These roles usually command the highest salaries within the academic hierarchy. Benefits and opportunities for research funding and leadership positions are typically more significant than in lower ranks.

Benefits Package Associated with California State Faculty Contracts

California State University faculty contracts often include a comprehensive benefits package, designed to support faculty members and their families. These packages typically include health insurance (medical, dental, vision), retirement plans (often with matching contributions from the institution), paid time off (vacation, sick leave, and holidays), and life insurance. Some contracts may also offer supplemental benefits, such as professional development funds, disability insurance, or tuition waivers.

The California State faculty contract negotiations are proving to be quite the rollercoaster. While everyone’s focused on the details of compensation and benefits, it’s hard not to also think about the glamorous world of fashion, like what’s happening at Saint Laurent Dior Paris Fashion Week. Ultimately, though, these high-profile events don’t directly impact the critical issues at hand for California State faculty.

Hopefully, the contract negotiations will reach a fair and reasonable resolution soon.

- Health Insurance: Comprehensive health insurance plans are a key benefit, often with options for coverage levels and varying co-pays and deductibles.

- Retirement Plans: Retirement plans, frequently a combination of defined-contribution and defined-benefit options, offer financial security for the future. Matching contributions by the institution are common.

- Paid Time Off: Faculty typically receive vacation, sick leave, and holidays, as well as other paid time off that varies depending on the contract terms.

- Other Benefits: Supplemental benefits may include professional development funds, disability insurance, tuition waivers for dependents, and other allowances, which may vary depending on the institution and department.

Compensation and Benefits Variations Across Departments and Institutions

Variations in compensation and benefits exist between departments and institutions within the California State University system. Factors influencing these variations include the department’s research focus, the institution’s financial resources, and the specific terms negotiated within each contract.

| Department | Compensation Structure | Benefits Package |

|---|---|---|

| Engineering | Higher base salaries due to high demand for specialized skills and potential for research grants. | Competitive health insurance and retirement plans, often with supplemental funding for research-related activities. |

| Humanities | Lower base salaries compared to STEM fields, potentially less emphasis on research funding. | Comprehensive health insurance and retirement plans, with focus on professional development opportunities. |

| Other Departments | Compensation structure varies based on specific needs and responsibilities. | Benefits package typically aligns with institutional standards, but may have variations depending on specific factors. |

Academic Freedom and Responsibilities: California State Faculty Contract

California State faculty contracts carefully define academic freedom, balancing the institution’s needs with the individual instructor’s right to pursue scholarly inquiry and expression. This crucial component protects the intellectual integrity of the institution and fosters a stimulating environment for both teaching and research. Understanding the specific parameters of academic freedom, along with the accompanying responsibilities, is essential for all parties involved.The concept of academic freedom is rooted in the belief that open inquiry and the exchange of ideas are fundamental to the pursuit of knowledge.

This freedom allows faculty members to explore various perspectives, engage in critical analysis, and contribute to the advancement of their respective disciplines without fear of reprisal. However, this freedom is not absolute; it is balanced against the responsibilities and obligations inherent in the faculty role.

California State faculty contract negotiations are proving tricky, with no easy solutions in sight. While the talks drag on, it’s interesting to note the current buzz surrounding the potential trade of Blues player Pavel Buchnevich, potentially impacting the team’s future. Hopefully, these external distractions won’t derail the faculty contract progress. It’s a long road ahead for both, and unfortunately, there’s no quick fix.

Definition of Academic Freedom

Academic freedom, as enshrined in many California State faculty contracts, is generally understood as the freedom to teach, conduct research, and publish without undue interference or censorship. This encompasses the ability to present different viewpoints, challenge conventional wisdom, and engage in critical dialogue within the boundaries of the established curriculum and the institution’s mission. This right is not absolute and is subject to certain limitations.

Specific Responsibilities of Faculty Members

Faculty members have specific responsibilities Artikeld in their contracts, which are integral to maintaining the integrity and efficacy of the educational process. These responsibilities extend beyond the classroom, encompassing the conduct of research, publication, and engagement with the broader academic community. These obligations ensure that the faculty member’s activities align with the institution’s goals and the overall academic environment.

- Adherence to the established curriculum and course requirements, ensuring alignment with the institution’s educational objectives.

- Maintaining professional standards in teaching and research, ensuring the quality of instruction and the integrity of scholarly work.

- Upholding ethical conduct in all academic activities, avoiding plagiarism and maintaining objectivity in research and instruction.

- Promoting respectful discourse and intellectual exchange among students and colleagues, fostering a supportive learning environment.

- Commitment to the institution’s values and policies, recognizing the importance of maintaining a harmonious and productive academic environment.

Limitations on Academic Freedom

While academic freedom is a cornerstone of the faculty role, it is not without limitations. These limitations are crucial to maintaining order, ensuring the integrity of the educational mission, and protecting the rights of others within the institution. Understanding these limitations is essential for both faculty and administrators.

- Compliance with Institutional Policies: Faculty members must adhere to the institution’s policies, including those related to student conduct, faculty conduct, and the use of university resources. These policies help ensure a structured and safe learning environment.

- Protection of Student Rights: Academic freedom cannot infringe upon the rights of students. The institution’s policies and procedures must protect students from discriminatory or harmful conduct by faculty members.

- Maintaining Institutional Reputation: Faculty actions that jeopardize the institution’s reputation or public image may be subject to review and possible restrictions. The institution’s commitment to maintaining a positive image must be balanced with the faculty member’s right to express their views.

- Avoiding Disruption of Educational Processes: Activities that substantially disrupt the educational process or create an unsafe learning environment are not protected under academic freedom. This includes actions that may negatively impact the well-being of students or colleagues.

Examples of Contract Provisions

California State faculty contracts, like any employment agreement, are meticulously crafted documents outlining the responsibilities and expectations of both the institution and the faculty member. Understanding the specifics of these contracts is crucial for both parties to ensure a mutually beneficial and productive working relationship. This section delves into key contract provisions related to teaching, research, service, and professional development, providing concrete examples to illustrate their practical application.

California State faculty contract negotiations are proving to be a bit of a bumpy road. While the specifics are still unfolding, it’s interesting to note the parallel discussions happening elsewhere, like the recent developments surrounding the .nu domain in Sweden. Apparently, the complexities of internet domain management in places like Niue .nu domain Sweden have some surprisingly similar challenges to those currently facing California State faculty contract agreements.

This might highlight the interconnectedness of various systems, even those seemingly disparate, when it comes to negotiations and resolving disputes. Hopefully, a productive solution is found for both the California State contract and the global digital landscape.

Teaching Responsibilities

Contract provisions regarding teaching Artikel the specifics of course assignments, including course load, preparation time, and student interaction. These provisions are essential for establishing clear expectations for both the instructor and the institution.

| Clause Category | Example Clause |

|---|---|

| Course Load | “The faculty member agrees to teach [number] courses per academic year, with a maximum/minimum load specified in the contract. These courses shall be distributed across the following disciplines: [List of disciplines].” |

| Preparation Time | “Faculty members are allotted [number] hours of preparation time per week for each course taught, in addition to assigned office hours.” |

| Student Interaction | “The faculty member agrees to maintain regular office hours and to be readily available for student consultation as needed.” |

The precise wording and stipulations regarding teaching responsibilities can vary significantly depending on the specific department, rank, and other factors. These clauses are critical for ensuring a balanced and efficient academic environment.

Research Obligations

Faculty research is a cornerstone of academic institutions, and contract provisions reflect this importance. These clauses may mandate specific research activities, allocate resources, and specify evaluation criteria.

| Clause Category | Example Clause |

|---|---|

| Research Activities | “The faculty member is expected to engage in [specific type of research] and to submit proposals to external funding agencies, as applicable.” |

| Research Resources | “The institution agrees to provide access to [specific research facilities] and [specific software] for the faculty member’s research endeavors.” |

| Research Evaluation | “The faculty member’s research performance will be evaluated annually based on [criteria such as publications, presentations, and grant submissions].” |

The level of research expectation varies greatly depending on the faculty member’s rank and department. Some contracts might require publications or grant applications, while others might focus on research development and mentorship.

Service Responsibilities

Service obligations, encompassing university committees, departmental tasks, and community outreach, are vital to the functioning of the institution.

| Clause Category | Example Clause |

|---|---|

| Committee Participation | “The faculty member agrees to participate in [number] university committees or departmental tasks each academic year.” |

| Departmental Service | “The faculty member is expected to participate in departmental activities, such as curriculum development and program reviews.” |

| Community Engagement | “The faculty member may be expected to engage in community outreach activities, such as presentations or workshops.” |

Service clauses are designed to ensure faculty members contribute to the overall university mission, both within the academic community and the broader community. The extent of service required can differ depending on the position and the institution’s priorities.

Professional Development

Contract provisions on professional development recognize the ongoing need for faculty members to enhance their skills and knowledge.

| Clause Category | Example Clause |

|---|---|

| Training Opportunities | “The institution will provide opportunities for professional development, such as workshops, conferences, and training programs, related to [specific areas].” |

| Continuing Education | “The faculty member is expected to engage in activities to enhance their skills and knowledge within their field of expertise.” |

| Funding for Development | “The institution may allocate funds for professional development activities related to teaching and research.” |

Professional development clauses support faculty members in maintaining current knowledge and skill sets, thus enhancing their teaching and research. The specifics of these provisions may vary according to the institution’s resources and priorities.

Potential Contract Changes

California State faculty contracts are dynamic documents, constantly adapting to shifting academic landscapes and external pressures. Understanding potential future changes is crucial for both faculty and administrators to anticipate and address evolving needs. These adjustments might involve compensation structures, workload expectations, or even the very definition of academic freedom.Analyzing potential shifts in these contracts requires considering economic realities, social trends, and evolving legal frameworks.

Future revisions will likely reflect the balance between maintaining academic excellence and responding to the realities of a changing world.

Future Trends in Compensation

Adjustments to compensation packages are a near-constant consideration in contract negotiations. Rising living costs and inflation frequently necessitate increases in base salary and supplemental benefits. A key trend will likely be a greater focus on cost-of-living adjustments (COLAs) tied to regional inflation rates, rather than flat increases. This approach ensures that faculty compensation remains relevant to local economic conditions.Another potential shift is the introduction of more performance-based incentives.

This might involve linking salary increases or bonuses to specific metrics like research output, grant acquisition, or student success. However, the design of such incentives needs to be carefully considered to avoid creating undue pressure on faculty and to ensure alignment with institutional goals. Furthermore, the potential for creating inequities between disciplines or institutions will require careful consideration during the design process.

Impact of External Economic Factors

External economic downturns or periods of rapid economic change often lead to scrutiny of public sector budgets, potentially affecting funding for higher education. Reduced funding could result in decreased resources allocated to faculty support services, research facilities, and overall academic programs. This might translate into contract provisions that limit faculty workloads, research grants, or even the hiring of new staff.For example, the 2008 financial crisis saw significant budget cuts in many state institutions, leading to reduced faculty salaries, hiring freezes, and limitations on research funding.

This highlights the importance of anticipating and mitigating the impact of economic uncertainty on faculty contracts. Similarly, a rapid increase in the cost of living could necessitate more frequent and significant COLA adjustments to maintain faculty purchasing power.

Potential Changes in Academic Freedom

The concept of academic freedom, a cornerstone of faculty contracts, is subject to ongoing interpretation. With increasing public scrutiny and concerns over certain viewpoints, contract provisions related to academic freedom may undergo revisions to address the balance between freedom of expression and potential harm or disruption. Examples of specific issues that might be addressed include guidelines on controversial research topics, restrictions on public statements by faculty, and the role of the institution in moderating potentially harmful speech.Careful consideration will need to be given to how any potential restrictions on academic freedom are framed and implemented to avoid stifling legitimate intellectual discourse and research.

Furthermore, clear guidelines will need to be established to address any potential misunderstandings regarding the boundaries of academic freedom and responsibilities. This could include the development of clear and concise statements on the institution’s commitment to academic freedom and procedures for addressing potential conflicts.

Conclusion

In conclusion, California State faculty contracts are complex documents that reflect the unique balance between academic freedom, institutional responsibilities, and evolving legal landscapes. This comprehensive overview provides a thorough understanding of the key components, potential challenges, and ongoing considerations surrounding these contracts. From the historical context to the potential future trends, this analysis offers a valuable resource for all stakeholders.

Expert Answers

What are common disputes arising from California State faculty contracts?

Common disputes often involve salary discrepancies, workload issues, concerns about academic freedom limitations, and problems with promotion procedures.

How do state laws impact faculty contracts?

State laws and university policies play a significant role in shaping the terms and conditions Artikeld in faculty contracts. These legal frameworks provide a foundation for the rights and responsibilities of both faculty and the institution.

What are the typical benefits associated with California State faculty contracts?

Benefits can vary depending on the specific position and institution. Typical benefits might include health insurance, retirement plans, and paid time off. A detailed analysis of compensation and benefits across different departments and institutions is crucial for a complete understanding.

What are potential future changes to California State faculty contracts?

Future changes might be influenced by economic shifts, evolving societal expectations, and adjustments to existing legal precedents. Factors like budgetary constraints or shifts in academic priorities can impact contract terms and conditions.